News

The raw liquid processed by the customer is sodium sulfate. The filtration flow rate is 5,000 liters per hour. The working hours every day are 2 to 3 hours. The customer requires a filter with a filtration accuracy of 20 microns, which is easy to clean and does not require frequent replacement of the filter element.

Based on the customer's process requirements, the following configuration was selected after a comprehensive assessment:

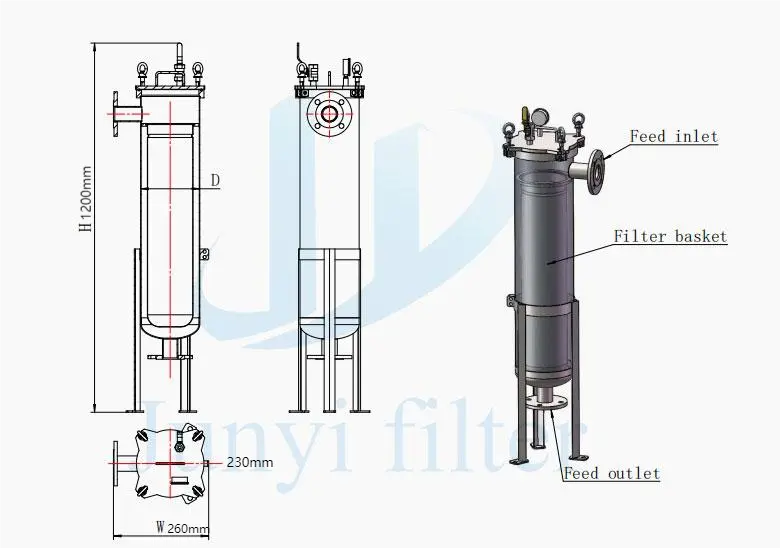

Machine: No. 2 bag filter

Filtration area: 0.5m³

Applicable temperature: 70° C -80° C

Cylinder material: SS316

Working hours: 3 hours

Core function: The interior of the cylinder is equipped with a stainless steel sintered mesh filter basket

The filtration accuracy can reach 5 microns, intercepting 95% of impurities. The mesh basket can be disassembled for cleaning.

This solution highly meets the customer's demands. The stainless steel sintered mesh filter basket is more durable than ordinary filter bags, reducing the frequency of filter bag replacement. Its excellent corrosion resistance and high-temperature resistance ensure a stable structure even in acidic and alkaline environments and under high-temperature working conditions. Secondly, in terms of filtration performance, the stainless steel sintered mesh filter basket adopts the metal mesh sintering process, with uniform pore size distribution and precision reaching the micrometer level. It can effectively intercept finer particle impurities and has a higher dirt-holding capacity, which extends the replacement cycle and reduces maintenance costs.

| Basic parameters | Model | JYSF-2# |

| filtration area | 0.5 square meters | |

| Flow rate | 40 m ³ /H | |

| main material | SS316 | |

| Wire Basket | Accuracy | 5 microns |

| Material | SS316 | |

| Quantity | 1 |

Junyi Copyright ? 2025 ALL rights reserved